While reading this short article, I suggest listening to the legendary song Thunderstruck by the legendary hard rock band AC/DC (although High Voltage might be more appropriate for the article given its title, the intro riff of Thunderstruck is by far the best the band has ever produced, and what’s more, the lyrics mention being awakened by an irresistible energy).

So there you have it, in 2025, several initiatives such as Open DC Alliance (ODCA), Shift2DC and the Current/OS Foundation are talking about and campaigning for the widespread introduction of DC microgrids, This is not about reviving the current war waged by Thomas Edison and Nikola Tesla, which ended with the adoption of the alternative standard, but about proposing a hybrid distribution mode that takes benefits from both sides. Today, high-voltage distribution networks (HVDC) are already well established, particularly in submarine transport, but what about medium-voltage (MVDC) and low-voltage (LVDC) networks? What about extra-low voltage (ELVDC), which is widely used in USB chargers and LED lighting? Why not do away with transformers that pile up in cardboard boxes because they are offered again and again with every new device purchased? We are talking about reducing material costs, increasing energy efficiency and improving device reliability.

However, this article does not discuss ELVDC networks, but rather larger industrial installations or electric vehicle charging stations. This article proposes three simple steps to consider in order to achieve a level of efficiency that will be seen as a standard in the near future.

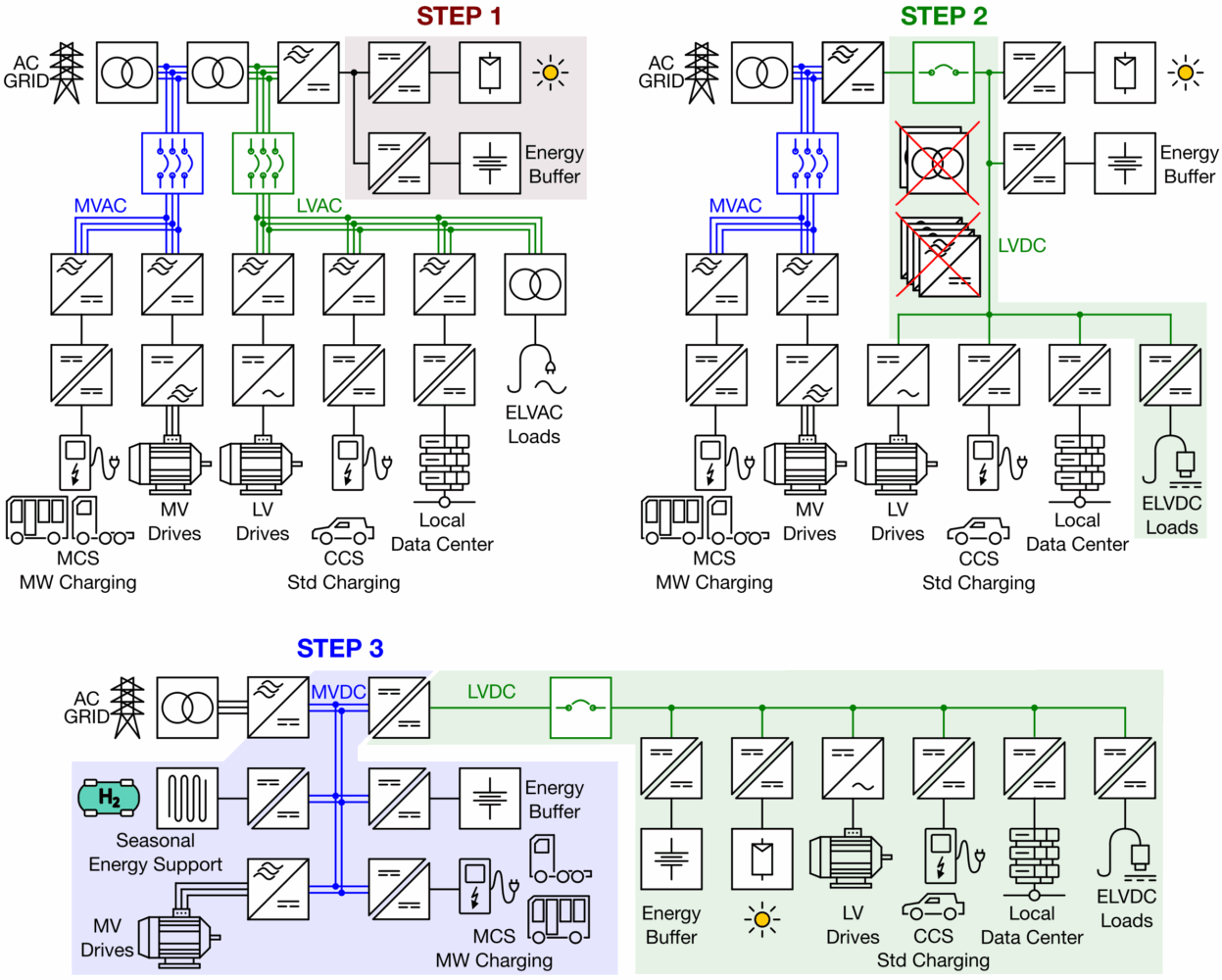

The first step is to catch up with what is currently considered state of the art. It usually consists of a connection to the AC distribution network, with several types of loads, medium or low voltage, but above all several energy production units and intermediate storage elements that act as energy buffers. Any available roof space is ideal for installing solar panels. It is also well established that fluctuations in solar production can be smoothed out by intermediate storage, commonly referred to as ‘peak shaving’. Discontinuous loads that operate intermittently, typically electric vehicle chargers, already pose a problem for distribution networks because any deviation from the expected consumption costs a lot of money. Installing an energy buffer solves the problem of these intermittences by handling power variations while ensuring continuous and stable consumption from the grid. These installations are not experimental; they are state-of-the-art technology that offers a proven financial advantage, simply by considering the cost of electricity consumption.

The second step is to consider a common DC bus to halve the number of power converters. In typical industrial networks, motors have a rectifier stage connected to the AC backbone, followed by a new inverter for the driving function. The well-established idea is to connect these DC buses together in the form of an intermediate LVDC microgrid that would connect generation and storage directly to the loads. In this way, semiconductor losses in power converters would be halved, boosting the efficiency and reliability of the system. The counterpoint comes with the introduction of a protection system called DC breaker, which is well established in DC railway networks but nevertheless more expensive than AC circuit breakers. It would appear that, at present, the initial cost of a DC microgrid is higher than that of an AC microgrid, but these costs would be offset by the benefits associated with operation. For an accurate assessment, a case-by-case analysis would be required, evaluating each system separately, but the good news is that there are more and more examples proving this hypothesis.

Finally, as a third step, the same should be done with the MVDC side in order to reap the same benefits as in the establishment of an LVDC network. One of the problems at these levels stems from the fact that protection systems become too expensive for economically viable operation. However, a new hope comes from power converters. Solid-state transformers (SSTs) are composed of modular, multi-stage elements that can be disconnected in the event of a fault in the network. Also, they can control or limit short-circuit currents, even in the event of faults originating from the converter itself. This technology has been around for decades under various names, including ‘dual active bridge’ (DAB), and enables isolated DC/DC conversion with a medium-frequency stage, drastically reducing the amount of ferromagnetic materials required. Although more efficient and less bulky, its cost remains prohibitive due to the lack of large-scale production.

I could stop there and say, ‘What are you waiting for? Go ahead, it’s so simple,’ but nothing is simple when it comes to changing industry standards or certifying new components. There is still no consensus on voltage levels alone. Europe seems to be proposing 650V for LVDC, while the US and China are going for 750V, all due to different AC voltage levels for commonly used motor drives. There is also a talk about 800V, which has suddenly emerged from the major players in data centres and other artificial intelligence providers. As for MVDC levels, we are hearing ±2kV or ±4kV, while others suggest ±1.5kV, ±3kV and ±4.5kV to adapt to the capabilities of existing semiconductors, provided that power converters are included in the discussions. There are also ±10kV or ±12kV, and even ±20kV or ±27kV, but perhaps it is not so important to go that far, as the whole point of the modular converter is that it can adapt to all levels.

For more information on modelling DC microgrids with semiconductor transformer-type converters, see this tutorial: https://pesc.blog/en/system-level-level-modeling-ans-simulation-of-mvdc-microgrids-featuring-solid-state-transformers/